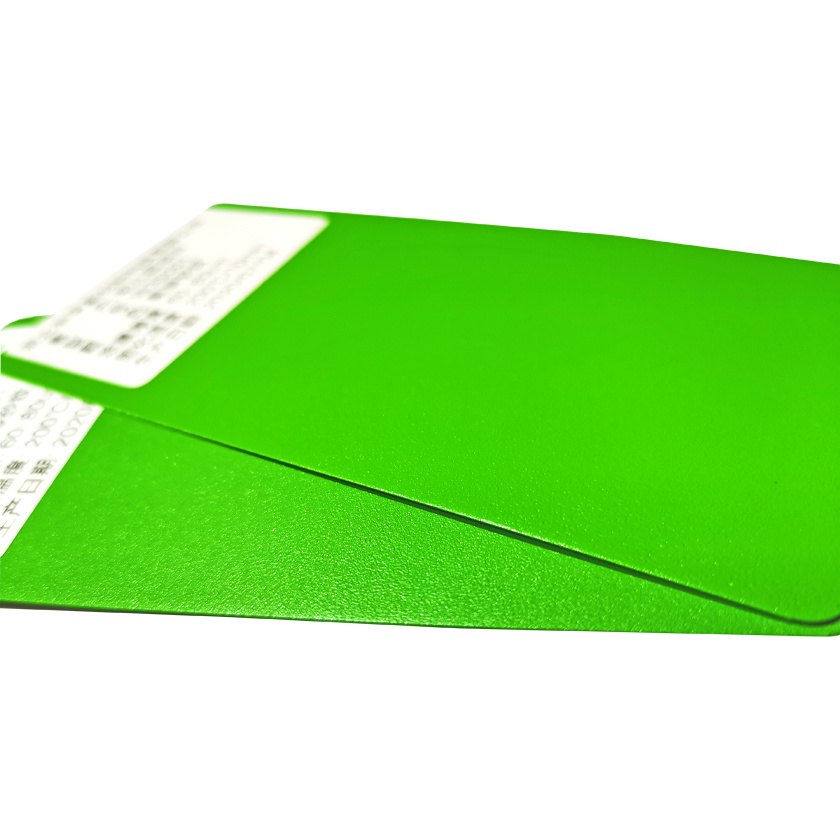

Green Sand Texture Powder Coating

Belongs to category:

Powder coating

18986804450

jojo@leaf-powder.com

Product details

What is Sand Texture Powder Coating?

Sand texture powder coating is a type of coating that combines the durability of powder coating with a unique textured finish. This type of coating is designed to provide a rugged, textured appearance that mimics the look of sand, making it a popular choice for various applications.

The formulation of green sand texture powder coating typically includes resins, pigments, and additives that enhance its performance and aesthetic appeal. Unlike traditional liquid paints, powder coatings are applied in a dry form and then cured under heat, resulting in a hard, durable finish that is resistant to chipping, scratching, and fading.

Benefits of Green Sand Texture Powder Coating

1. Eco-Friendly: One of the primary advantages of green sand texture powder coating is its environmentally friendly nature. The use of natural materials and the absence of volatile organic compounds (VOCs) make it a safer choice for both the environment and human health.

2. Durability: Powder coatings are known for their exceptional durability. The curing process creates a strong bond between the coating and the substrate, making it resistant to wear and tear. This durability is particularly beneficial for outdoor applications where exposure to harsh weather conditions is a concern.

3. Aesthetic Appeal: The textured finish of green sand texture powder coating provides a unique and visually appealing look. The sand-like texture can enhance the design of various products, making them stand out in a competitive market.

4. Versatility: This type of coating can be applied to a wide range of substrates, including metal, wood, and plastic. Its versatility makes it suitable for various industries, from automotive to furniture manufacturing.

5. Low Maintenance: Once applied, green sand texture powder coating requires minimal maintenance. Its resistance to corrosion and fading means that products coated with this finish can retain their appearance for years with little effort.

Applications of Green Sand Texture Powder Coating

Green sand texture powder coating is used in a variety of applications across different industries. Some of the most common applications include:

1. Automotive Industry: In the automotive sector, green sand texture powder coating is often used for wheels, bumpers, and other exterior components. The durable finish protects these parts from scratches and damage while providing a stylish appearance.

2. Furniture Manufacturing: Many furniture manufacturers are turning to green sand texture powder coating to enhance the look and durability of their products. This coating can be applied to metal frames, tables, and chairs, providing a unique finish that appeals to consumers.

3. Architectural Elements: In architecture, green sand texture powder coating is used for various elements, including railings, fences, and outdoor fixtures. Its weather-resistant properties make it an ideal choice for outdoor applications where exposure to the elements is a concern.

4. Consumer Products: Many consumer products, such as appliances and electronics, benefit from the use of green sand texture powder coating. The coating not only enhances the aesthetic appeal but also provides a protective layer that extends the product's lifespan.

The Application Process

The application of green sand texture powder coating involves several steps to ensure a high-quality finish.

1. Surface Preparation: Before applying the coating, the surface must be thoroughly cleaned and prepared. This may involve sanding, blasting, or chemical cleaning to remove any dirt, grease, or previous coatings. Proper surface preparation is crucial for achieving optimal adhesion and durability.

2. Powder Application: Once the surface is prepared, the powder coating is applied using an electrostatic spray gun. The powder particles are charged, allowing them to adhere to the surface evenly. This method ensures a uniform application and minimizes waste.

3. Curing: After application, the coated item is placed in a curing oven. The heat causes the powder to melt and flow, forming a smooth, even finish. The curing process typically takes 10 to 30 minutes at temperatures ranging from 350 to 400 degrees Fahrenheit, depending on the specific formulation.

4. Cooling and Inspection: Once cured, the coated item is allowed to cool. After cooling, it undergoes a thorough inspection to ensure that the finish meets quality standards. Any defects can be addressed at this stage.

关键词: Green Sand Texture Powder Coating

Related products

Get product quotation

Contact Information

Office address: 910, Guangsheng Building, Xiling District, Yichang City, Hubei Province

Factory Address: Taibaochang Village, Baiyang Town, Baiyang Industrial Park, High-tech Zone, Yichang City, Hubei Province, P.R.CHINA

Telephone:18986804450

E-mail:jojo@leaf-powder.com

Copyright©2024 All Rights Reserved of Hubei Tianlang Nanotechnology Co., Ltd.